A Community of Sharing and Making

Unleash Your Creativity with Our Cooperatively-Funded Makerspace!

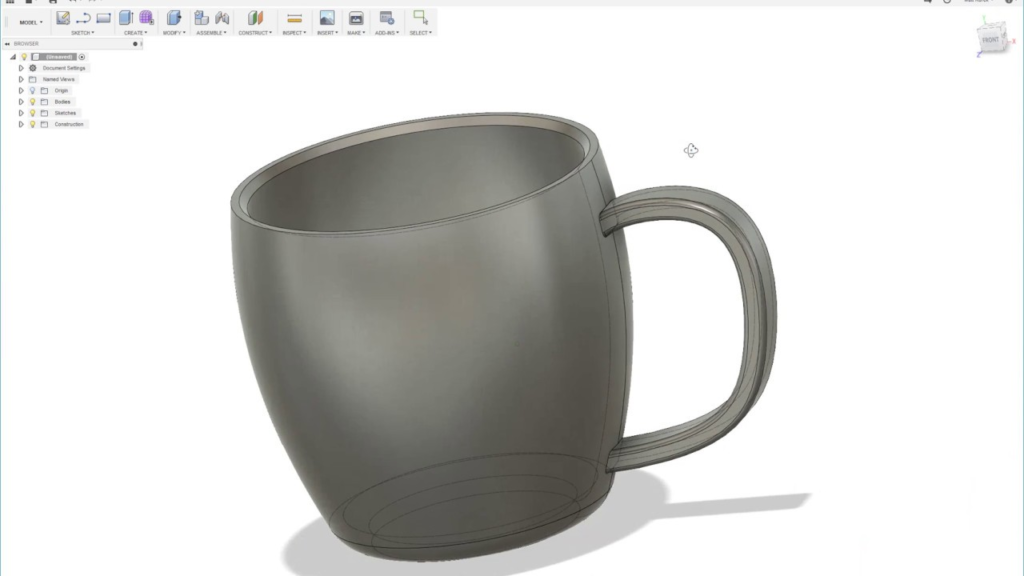

At our makerspace, we believe in the power of collaboration and creativity. Join our vibrant community of hobbyists from all walks of life and gain access to a fully-equipped studio where you can build, create, and invent to your heart’s content. With every donation and membership fee, you contribute directly to keeping our makerspace up and running for all members. From 3D-printing to laser cutting, sewing to welding, woodworking to electronics – we have the tools and resources you need for any project or passion. Don’t let your creativity be limited by space or lack of equipment – join us today!

Please contact us to arrange a tour, or stop by during our weekly open-shop night on Tuesdays!

Full Keyholder memberships are $40 per month ($50 for families) and non-keyholder memberships are $20 per month.

A Community of Sharing and Making Read More »