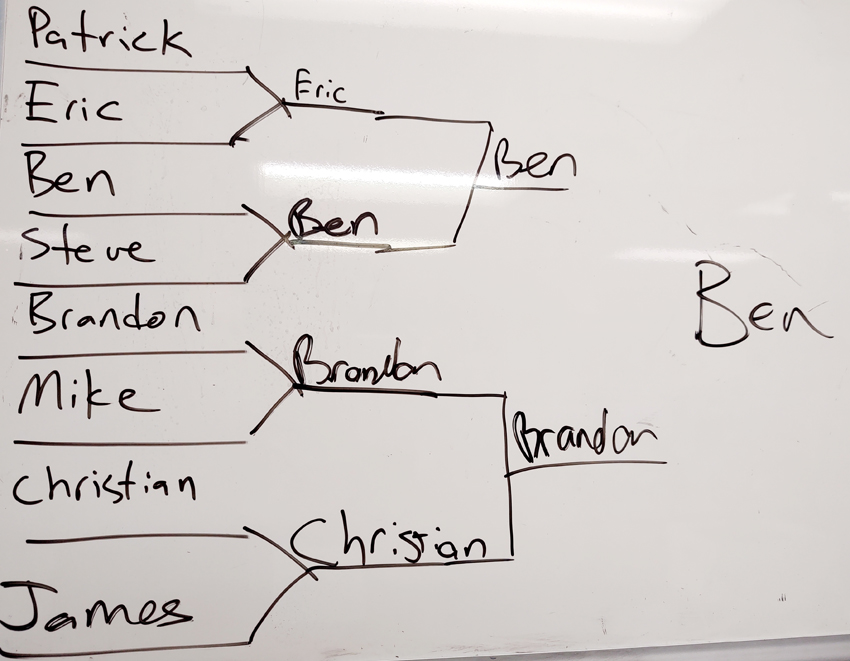

RC Car Battle Results

On February 25th, eight makers participated in the Sumo Battle that we’ve been preparing for since January. It was a raucous evening of smashing plastic and cheering crowds. Afterward we took apart a few cars to see how they worked – near the end of the video Ben even explains how he combined the front […]

RC Car Battle Results Read More »