Progress on the new Power Wheels racing car (Code Name STEVE) continues at a good pace! We’ve completed our innovative wood torsion box frame and are starting to lay out the other components for mounting. Here’s the recap:

The overall dimensions of the cart are 4′ in length (to make good use of our raw material) by 29″ in width (to drive through the narrowest doorway in the shop). Once we’d cut the torsion box skins to this size, we set them on the bench and started laying out the wheels and controls. Here’s James working on the seating position and handlebar layout:

Next, we started working on the internal bracing grid, using construction grade 2×4 boards ripped in half. We did this instead of just buying 2x2s because the larger boards tend to be straighter, higher-quality wood. After cutting the grid boards to length, we cut half-lap joints in them so they could cross while maintaining at least a portion of the grain all the way across the chassis.

Once everything is glued up, you can start to see the merit of this design – it’s very stiff, but incredibly lightweight. I don’t have any measurements of a steel frame to compare to, but at 21 lbs this will be hard to beat. And with the frame propped up on rollers at the axle locations and Eric sitting in the driver’s seat, there was no visible deflection.

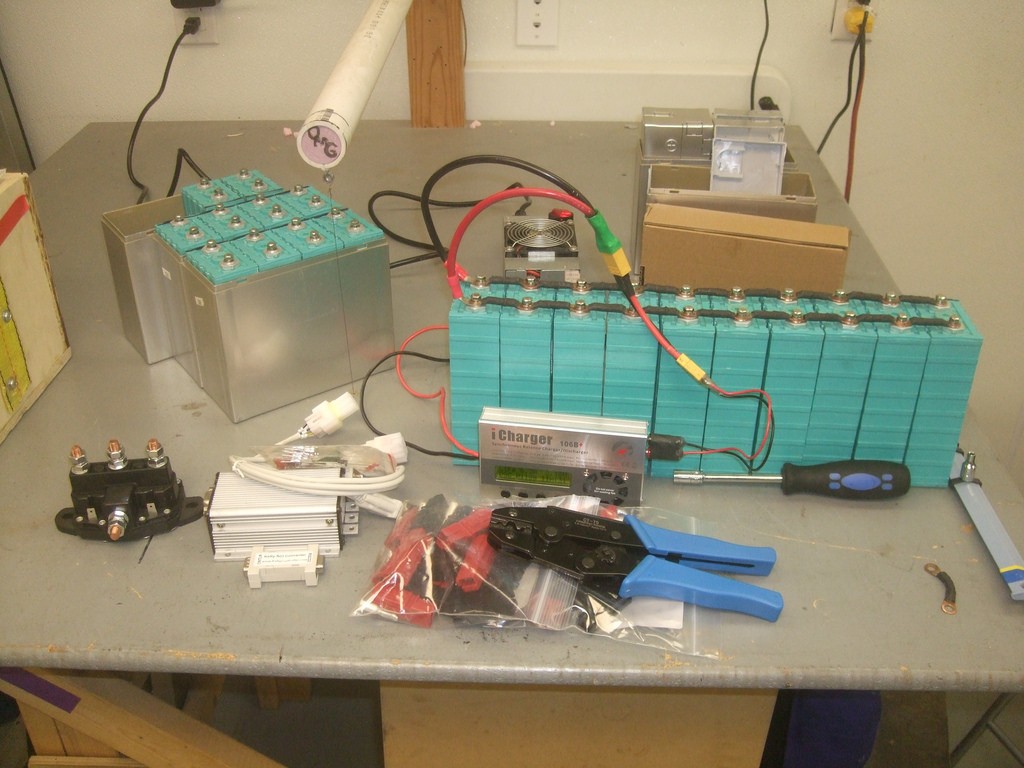

Finally, our new batteries are in. These are BatterySpace LiFePo4 20 Ah cells, approved for us by the PRS Sanctioning Body. Right out of the box, we divided the cells into two packs and set about bottom-balancing each. Basically, we wired the cells up in parallel and did a deep discharge to 2.6 volts, putting every cell at the same minimum state of charge. Then, once they’re wired back in series we charge until the first cell hits a maximum safe voltage, setting the capacity of the pack equal to the weakest single cell. This way, we can charge and discharge without needing complicated balancing or monitoring. The minimum pack voltage is 2.6 volts per cell, and in practice we’ll set our cutoff at 28 volts or more for a 10-cell pack. The maximum voltage is whatever the pack happens to be at when one cell peaks, but we’ll generally charge to around 34 volts. As it turns out, all our cells finish charging in balance to at least 10 mV, the resolution of our multimeter. Build a sturdy box to contain and protect the cells, and we’re ready to race!

Next up, we’ll be working on the axles and steering, and then we can get to mounting motors and electronics. Stop by and give us a hand!