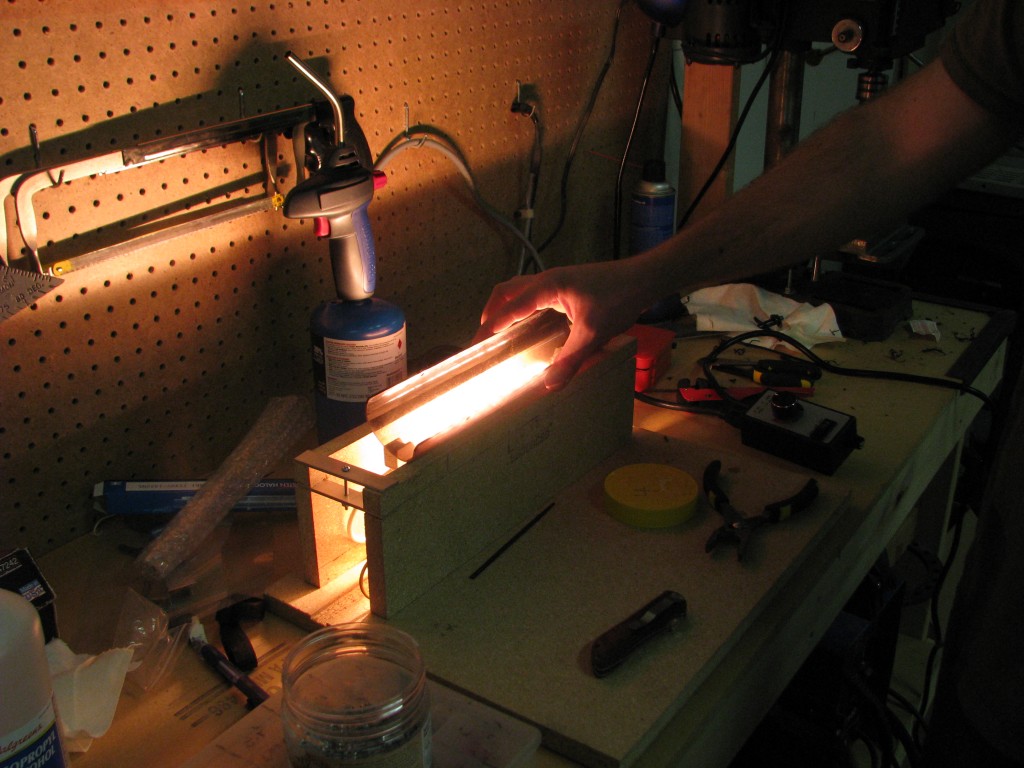

The acrylic heater is nearing completion (design shameless copied from a hack-a-day post).

I still need to make a few more tweaks to it before it’s ready for use. There’s a minute amount of water leaking around the barbs, but that’s easily fixed with some clamps. I’d also like to find something better than a gladware container for the reservoir. Then there’s the brightness… I don’t think the control I’m using was made to dim something with 0.1 ohms of resistance.

Yes, the overhead lights are on in this picture. Yes, the controls are set to their lowest possible setting. Yes, it’s that bright through the smoked acrylic. I actually grabbed a welding helmet a few seconds after this shot.

I’ll post more details and possibly a tutorial video when I get this thing ready.

Nice work, James!

You said it drips only a bit at the barbs… does this mean that the JBWelded ends is sealed good?

Yup, JB weld was a great success. I think we’re going to need a heat shield for the stuff below. The wood started smoking after a minute or so on low (even with the water bars running. I have an idea, though. My home news paper sold off sheets of aluminum for 50c that were left overs from the printing process. I could make a semi circle to go under the light and run it up to the coolers to cool the shield a little bit.

Thanks for the help with this, Kevin. It’s turning out great.

Hey Guys – I’ve been looking for an Omaha hackerspace/makerspace for a few months now. I’m with the Detroit hackerspace. Can someone shoot me an email so we can touch bases? 1) I wanna chat Maker Faire Detroit with you. Probably won’t make it to Maker Faire: KC. 2) I have a contact at ConAgra what wants to work with a local hackerspace. Been trying to hook him up with someone. Give me a shout. Good luck with setting-up a space. It is both incredibly frustrating and amazingly fun.